HONEYPOT EXTRAKTOR

Made in Germany

Make the Difference

Research & Development

It is our ambitious goal to develop individualized and innovative solutions that add significant value for our customers. Through a range of solutions, we have adapted our product portfolio in recent years according to market requirements. Product innovations, integrated solutions, as well as a great understanding of our customers’ applications and wishes define our products.

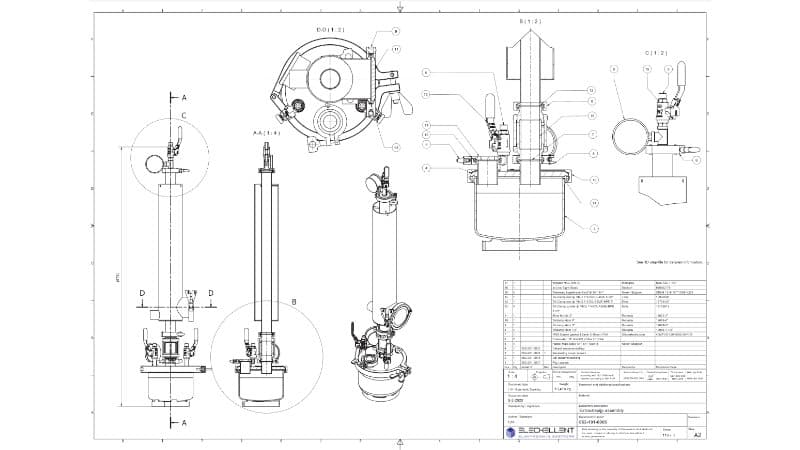

Filling lid with quick release couplings

The filling lid has a nozzle that ensures even distribution of the solvent without channeling the biomass. This also helps to prevent violent agitation of the biomass and release of unwanted waxes and chlorophyll.

Columns in various configurations and sizes

All 4 material columns have a standard volume of 4.4 liters per column. It is possible to stack one column on top of another. The modular design ensures individual loading and allows the user to “scale up” or “scale down” at any time. A fully jacketed drip tray and a jacketed tray are included for quick, easy heating and cooling. Each HONEYpot Loop System is constructed of high quality 316 L stainless steel. Also included are all quick disconnects, hose connectors, viewing windows, valves, tubing and a stainless strainer. For professional storage and safe transportation, your extractor comes in a space-saving, sturdy and lockable aluminum box with handles. Space-saving and clearly stowed, always ready to hand and quick to use.

Viewing window

The HONEYpot extractors include viewing windows to continuously observe the extraction process and obtain a consistent end product.

Collection container for quick and easy pouring processes

The bottom of the collecting vessel can be dismantled to separate the extract quickly and easily.

Flat bottom of the collection container

After the pouring process, the bottom of the collecting vessel can be dismantled. This feature ensures a flawless production process and even the most difficult substances are discharged quickly and without residue. The stainless steel containers prevent product residue due to a special surface and are quick to clean due to their contour. The ergonomic scraper included in the scope of delivery discharges the end product quickly, gently and without residue.

HONEYPOT EXTRAKTOR DETAILS

Performance within 8 operating hours

A key feature is the ability to perform multiple extractions simultaneously.

Quantity per flow

Dimensions

lbs / 8 hrs.

Compressed air needed

Frame material

Column material

Material tubes

Clamp connections

Seals Clamp connections

Stainless steel screen mesh

Quick coupling

Viewing window

Working pressure

Maximum pressure

Collection container

Compressed air connection

Pressure safety valve

Scraper for easy removal of the extract

Suitable solvents

Until 15L

700 mm x 800mm

25-30

1 m3

Steel laser cut

316 L stainless steel

316 L stainless steel, reinforced

316 L stainless steel

Viton

Stainless steel

Custom Dry-Break

Yes

10-40psi

350psi

316 L stainless steel

3/4” NPT

Standard

Included 316 L stainless steel

100% Butane, 100% Propane, all Corresponding Mixtures.