Greenhouse Rolling Tables

The width of your roller tables is an important point for the efficiency of your cultivation project.

The perfect table width for cannabis cultivation

rolling tables is an important consideration when planning an indoor or greenhouse cannabis growing facility. The size of the rolling tables in your facility will have a big impact on how efficiently your grow space is utilised and how easily gardeners can reach the cannabis plants for defoliation or other maintenance tasks. All of this adds to the cost of producing your cannabis products and should be well thought out from the start.

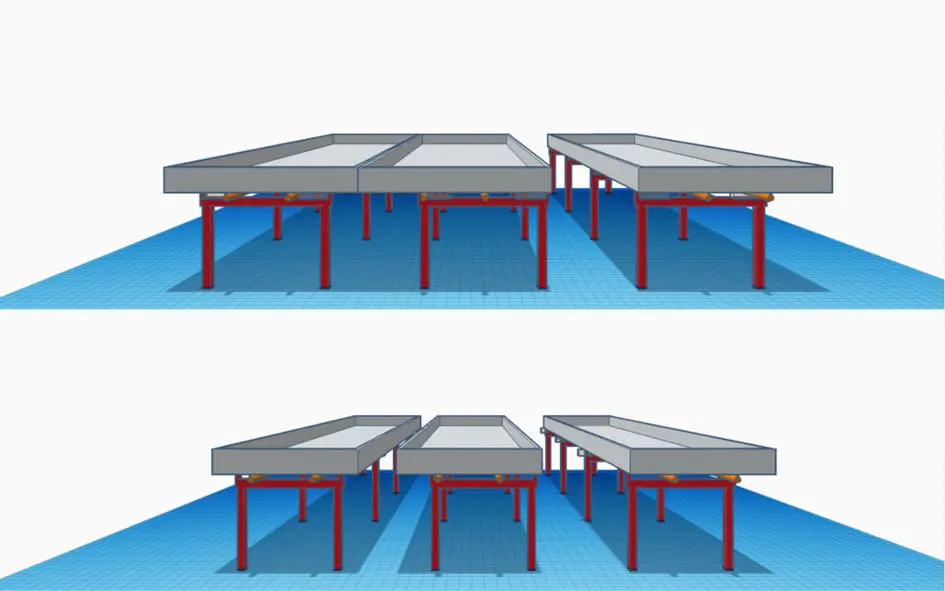

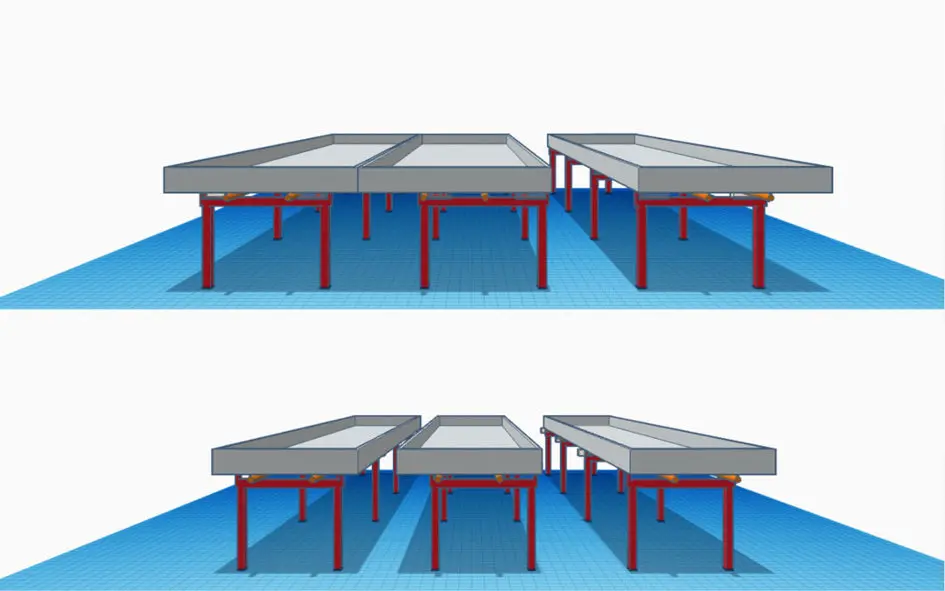

Top: 1.6 m wide roller tables

Bottom: 1.2 m wide roller tables

Technical aspects of roller tables that determine the size of rolling tables

I recently had a conversation with a leading horticulture company that installs rolling benches in many CBD and medical cannabis facilities. She has a lot of experience with technical solutions in greenhouse and indoor cultivation and extensive knowledge of technical aspects of roller tables.

When I designed my first indoor growing space, I was interested in getting roller tables that were no wider than 1.20 m. We recommend wider roller tables. We recommend wider roller tables because they make better use of the growing space and lighting. I mean, I love efficiency, but at the time I was thinking more about the ergonomic aspects of practical work. I thought that with 1.2 m wide tables, workers only have to reach plants that are 60 centimetres deep on the table. Even very short people with short arms can thus reach the plants comfortably.

In this drawing, the right-hand roller tables are moved to open an aisle.

Top: 1.6 m wide roller tables

Bottom: 1.2 m wide roller tables

It is easy to see that you make much better use of your valuable cultivation area with the 1.6 m wide roller tables than with 1.2 wide roller benches. I have calculated a 16% better use of space with 1.6 m wide roller benches. Especially when growing indoors, this makes a big difference as the floor space is much more expensive than outdoors or in greenhouses. Just think of all the lights.

Ergonomic requirements compared to technical requirements for roller tables

Unfortunately, not only ergonomic aspects form the requirements for roller tables, but also gravity and structural stability. For example, it turned out that roller benches with a width of 1.20 m can only be moved by 12.5 cm on each side. This means that if we have two roller benches next to each other and move them both so that we get an aisle between them, we only get 25 cm of aisle width. This is far too little for workers to walk through these two roller benches to do defoliation or other plant care work.

For structural reasons, it is not possible with conventional roller tables to move them even further to the side. This is because the table could then either tip over the edge and fall down or the structural stability would suffer. So, to get an aisle width of about 75 cm, which is a recommended working distance between two roller tables, we need 50 cm of “dead space” between two 1.2m wide roller tables.

In this 50cm you cannot place plants to use your rent or light energy efficiently.

Fortunately, this problem can be at least partially solved with wider roller tables. With 2m wide tables, you can move each table 35cm per side – making 70cm aisles without creating unused space between the rolling tables. However, with 2m wide tables, it is very difficult to reach the plants in the middle of each table, especially for small people. You have to stretch your arms out 1 metre to reach the plants in the middle of the table. So I would think about a compromise between 1.2 m and 2 m wide tables.

I came to the conclusion that 1.6m wide tables are probably often the best compromise for cannabis cultivation.

2m is still the best choice for ornamental flowers or greenhouses for low-growing herbs. In these cases, however, workers also do not have to reach into a dense “hedge” of tall, bushy plants, but can reach all plants from above, as flowers and herbs are often much lower than cannabis plants.

To illustrate the assumptions just discussed, I have created a couple of CAD drawings to visually illustrate the problem with verroll width and unused aisle.

Fixed path width for better ventilation

If we aim for 75 cm wide aisles between the roller tables when we roll them into the outermost positions, we still have that 25 centimetres of dead space between the 1.6 m wide roller benches. What at first sight appears to be highly inefficient, however, turns out to be a great advantage in large cultivation areas. Because all these gaps in the cultivation ensure homogeneous ventilation and a better microclimate in the cannabis forest. Also, all the side branches of the plants positioned on the sides of each table are exposed to the light sources mounted on top, so we can harvest more flowers of higher quality at harvest time.

Another advantage of the fixed path width for the 1.6 m wide roller tables: you don’t have to move all the roller benches in your room aside to get an aisle somewhere in the middle of the room. That’s why we have this fixed path width of 25 cm, which corresponds exactly to the rolling distance to each side of the 1.6m roller benches.

To round off the roller table topic:

In the end, you are free to decide which table width best suits your own cultivation project. Now you could at least understand some thoughts that can be taken into account when planning and designing a cannabis cultivation project. In the end, it is entirely up to you whether you want to use larger dead spaces, wider tables or narrow aisle widths.

Don’t hesitate to contact info@ellecxellent.com if you need help or advice with your cannabis growing project. Our team of experienced horticultural engineers will be happy to help!